TASKLED - Smart LED drivers

|

|

home > products (halltg)

Halltg Power Toggle Switch:

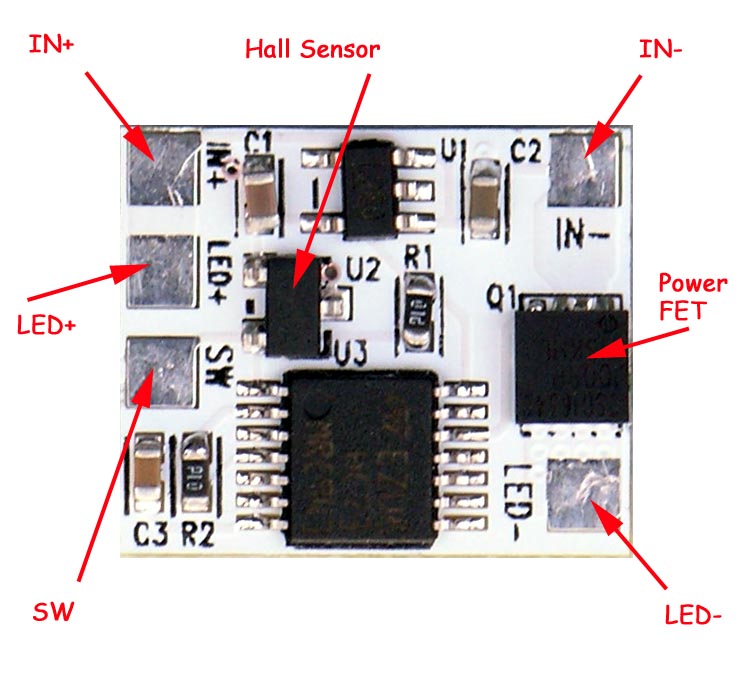

Refer to the following picture:

The bottom of the Halltg board has no components and would typically mount using the supplied double sided adhesive thermal pad material to a heatsink (body of the light). The Hall Sensor (U2) can be activated by the N or S side of a magnet from above or the N or S side of a magnet from below the PCB.

Note that the Halltg board is a toggle action switch (unlike the Hallsw board). The Halltg board responds to either the N or S side of a magnet of sufficent strength. When power is first applied the Halltg board will power up with the FET turned off. Bring a magnet close enough and the Halltg will toggle to the on state and the magnet can then be removed. To turn the Halltg board back off, bring a magnet close enough and it will toggle off and the magnet can then be removed. This action can be repeated as needed, hence the Toggle action.

Note that since the Halltg board is a toggle action switch, care must be taken to not accidentally turn on the board with an accidental application of an extraneous magnet. i.e. when storing a light or other device that has the power switched via the Halltg board one must be careful that it doen't turn on in storage.

The power FET (Q1) has vias under the FET to the bottom side of the PCB to provide a thermal path in high current applications. The on resistance of the FET is very low (typically less than 6 milliohms) and even at 10A total dissipation would only be (10 x 10 x 0.006) = 0.6W, which can easily be handled by a modest heatsink or attachment to the body of the light.

The supplied thermal pad material is nominally 0.25mm thick, white in colour and will conform to the heatsink and PCB surfaces to provide an excellent thermal path. Please ensure the heatsink and bottom of the HALLTG are cleaned of any grease or contaminants that would prevent the adhesive from properly bonding. Pressure should also be applied to help set the adhesive, refer to the datasheet for more information.

The thermal pad material (Li98 100 0.25mm) specifications can be found in the datasheet a copy of which is available here. The Li98 material provides a good compromise between the cost of the material and its thermal performance. The material is white in colour and has a protective cover on both sides that must be removed to expose the adhesive. Note, it is recommended to remove the Red protective material first and fix the pad to the heatsink or the HALLTG prior to removing the white protective material. The adhesive is an acrylic base and takes up to 24 hours for fully cure/set. After a few thermal cycles and 24 - 48 hours the bond will become stronger and the thermal conductivity will improve.

Connecting the Halltg to a LED or bulb (direct driven):

The following shows how the Halltg board is connected to a simple load like a direct driven LED. Connections are the same as for the Hallsw board.

Connecting the Halltg to a LED driver:

The following shows how the Halltg board is connected to an active load such as a LED driver.

Connecting the Halltg to a TaskLED flex driver:

The following shows how the Halltg board is connected to a simple load like a direct driven LED. In this case the Halltg SW output signal and the FET output is not used.

SWA is also called SW+ on the d2flex driver.

SWB is also called SW- on the d2flex driver and SWG on the maxflex driver.

Note it is very important to wire the IN- of the Halltg board to the SWB/SW-/SWG connection point on the flex drivers. This is to provide a 'quiet' ground connection for the Halltg board.

Connecting the Halltg to a inductive load such as a HID driver:

When an inductive load needs to be switch, the an external diode is require to protect the FET from inductive spikes. Inductive loads such as a relay, a HID driver, solenoid etc require the addition of the diode as shown below. Any small signal silicon diode can be used, e.g. 1N4148.

home | products | technical | order products | contact

©2025 TaskLED. All Rights Reserved.